The Future of Woodworking

The future of woodworking is an exciting and constantly evolving field, with new technologies and techniques being developed all the time. From the adoption of digital fabrication techniques to the use of advanced materials and automation, the woodworking industry is constantly evolving to meet the changing needs and demands of consumers and businesses.

The Future of Woodworking: Emerging Trends and Techniques

As a centuries-old trade, woodworking has evolved significantly over time, and it continues to do so today. So lets jump right in and explore some of the emerging trends and techniques that are shaping the future of woodworking.

Digital Fabrication

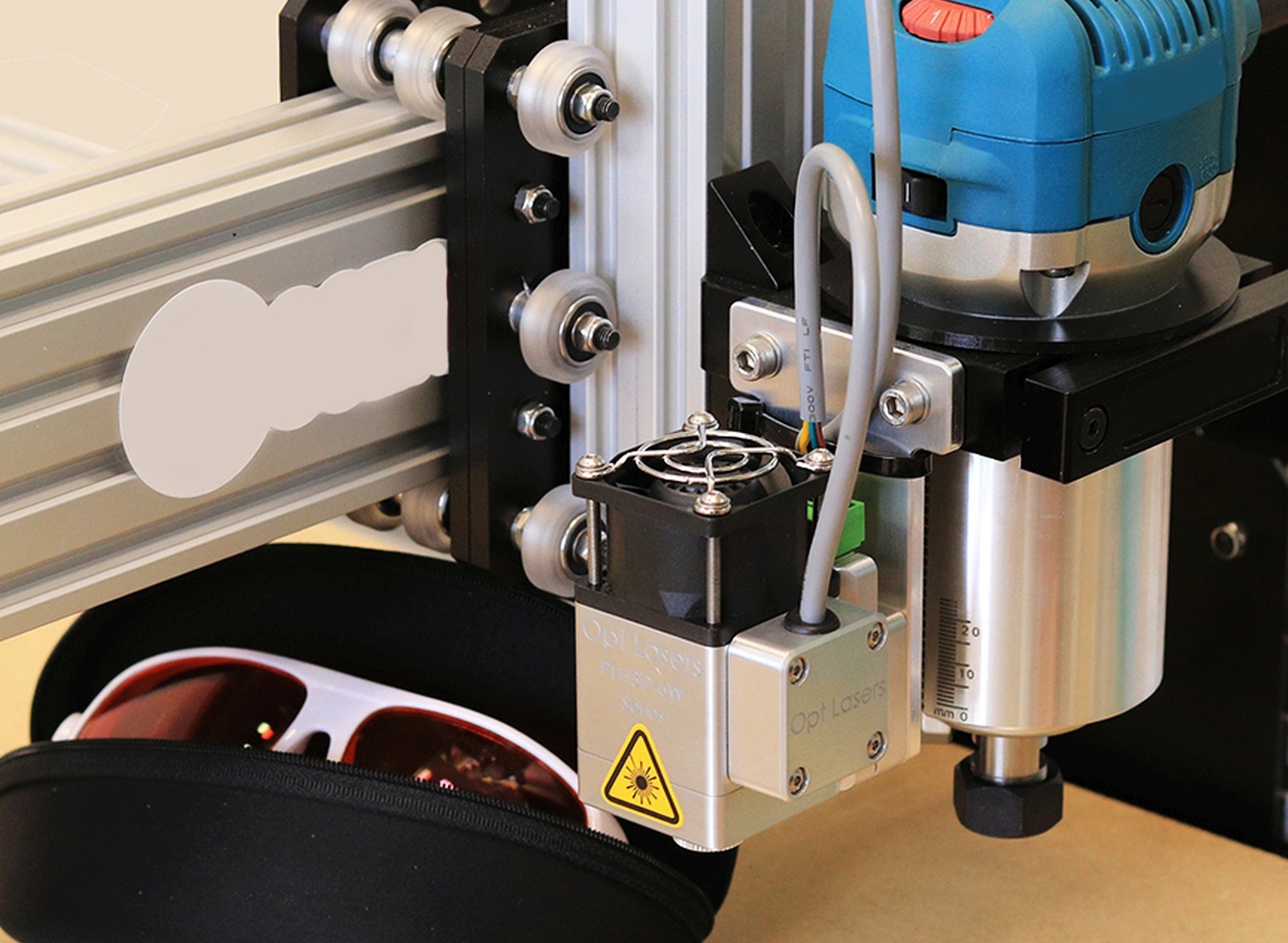

One trend that is gaining traction in the world of woodworking is the use of digital fabrication techniques, such as CNC routing (computer numerical control), 3D printing and laser cutters. These techniques allow us woodworkers to create highly precise and complex designs not only with a level of efficiency and accuracy that was once previously unattainable but also digital fabrication allows for the creation of custom one-off pieces, making it an ideal solution for small-batch or bespoke manufacturing.

One way that traditional woodworking techniques can be combined with digital fabrication is through the use of templates and guides. For example, we could use a CNC router to create a precise template for a hand-carved piece, or a laser cutter to create a guide for a complex joint. This can help to speed up the production process and ensure that the final product is accurate and consistent.

Another way that digital fabrication can be used in combination with traditional techniques is by incorporating digital tools into the design process. We could use 3D modeling software to design a piece and then use a CNC router to cut out the individual parts. This allows us to create highly complex and customized pieces that would be difficult or impossible to create using traditional methods alone.

Sustainable Practices

Sustainability is a growing concern for the future of woodworking in the woodworking industry. As a result, for the future of woodworking there is a push towards using eco-friendly materials and practices in woodworking.

This includes the use of reclaimed or recycled wood, as well as the adoption of energy-efficient manufacturing processes. Some woodworkers are even experimenting with alternative materials, such as bamboo or hemp, as a way to reduce their environmental impact.

There are several other sustainable practices that we as woodworkers can adopt to reduce the environmental impact and contribute to the future of woodworking:

- Use of non-toxic and low-VOC (volatile organic compound) finishes: Traditional wood finishes can release harmful chemicals into the air, which can be harmful to humans and the environment. Non-toxic and low-VOC finishes are a safer and more sustainable option.

- Responsible sourcing: Choosing wood from sustainable forests or reclaimed wood helps to reduce the impact of logging on the environment. Woodworkers can also look for wood that has been certified by organizations such as the Forest Stewardship Council (FSC) or the Rainforest Alliance.

- Energy efficiency: Woodworking can be energy-intensive, so using energy-efficient tools and equipment can help reduce the carbon footprint of a workshop. Woodworkers can also invest in renewable energy sources, such as solar panels, to power their workshop.

- Waste reduction: Woodworkers can minimize waste by carefully planning their projects and utilizing as much of the wood as possible. They can also look for ways to repurpose or recycle wood scraps and sawdust, such as using it as mulch or fuel.

For the future of woodworking, by adopting these and other sustainable practices, we as woodworkers can not only reduce our environmental impact, but also contribute to the overall sustainability of the woodworking industry.

Advanced Finishing Techniques

In the past, wood finishing was a time-consuming and labor-intensive process that required a high level of skill and experience. However in the future of woodworking, recent advances in technology have made it possible to achieve professional-quality finishes more quickly and easily.

One key advancement in wood finishing techniques is the use of spray finishing equipment. Wood finishing often required the use of brushes or rollers to apply stains, paints, and topcoats, which could be time-consuming and produce inconsistent results. In the future of woodworking, with the use of spray finishing equipment, woodworkers can achieve a more even and consistent finish with less effort.

There are several types of spray finishing equipment available, ranging from simple hand-held spray guns to more advanced systems that use compressed air or high-pressure pumps to atomize the finish. Some spray finishing systems even include features such as adjustable spray patterns, variable flow control, and built-in filters to help achieve a professional-quality finish.

In addition to the use of spray finishing equipment, there have also been significant advancements in the formulations of wood finishes themselves. Modern stains, paints, and topcoats are often more durable and easier to apply than their predecessors, thanks to the use of new technologies and materials. For example, some finishes now include UV inhibitors to help prevent fading, while others are designed to be scratch-resistant or water-repellent.

The use of advanced finishing techniques has the potential to significantly improve the speed and quality of the wood finishing process. By using the latest equipment and finishes, we can achieve professional-quality results with less effort and in less time.

Increased Automation

As with many other industries concerned about the future, automation is beginning to play a larger role in the future of woodworking. While this trend is still in its early stages, it has the potential to revolutionize the way that wood products are manufactured.

Increased automation in woodworking can be seen in many forms, ranging from simple mechanical devices to complex robotic systems. Some examples of automated woodworking equipment include:

- Automatic saws: These saws use sensors and computer control to accurately cut wood to size with minimal human intervention. This can improve the speed and accuracy of the cutting process, as well as reduce the risk of injury to workers.

- Automatic lathes: Similar to automatic saws, these lathes use computer control to turn wood and other materials with a high level of precision. Automatic lathes can be used to create a wide range of products, from furniture legs and spindles to decorative bowls and vases.

- Robotic sanding and finishing systems: These systems use specialized robots to sand and finish wood products with a high level of precision and consistency. These systems can improve the speed and efficiency of the finishing process, as well as reduce the risk of injury to workers.

- Smart power tools: Some power tools, such as routers and sanders, are now being equipped with sensors and connectivity features that allow them to be controlled and monitored remotely. This can improve the accuracy and efficiency of these tools, as well as provide valuable data on their usage and performance.

So in the future of woodworking, automation has the potential to improve the efficiency and productivity of woodworking operations, it is important to note that it is not a replacement for us human workers. Automated systems can perform tasks with a high level of accuracy and consistency, but they still require human oversight and maintenance. In addition, automation is likely to lead to the creation of new jobs in fields such as programming, maintenance, and data analysis.

The increased use of automation in woodworking is a trend that is likely to continue in the future of woodworking in the coming years. As for the future of woodworkers, well as technology advances and automation becomes more prevalent, it will be important for woodworkers and industry professionals to stay up-to-date on the latest developments and to adapt to new technologies as they become available.

A Bright Future for Woodworking

The future of woodworking is looking bright, with a number of exciting trends and techniques on the horizon.

One trend that is likely to continue in the future of woodworking is the rise of e-commerce and digital platforms. As more and more consumers turn to the internet to find and purchase wood products, woodworkers are using online marketplaces and social media to reach a wider audience and sell their products directly to consumers. This trend is especially important for small- and medium-sized businesses, which may not have the resources to operate a traditional brick-and-mortar storefront.

Another trend that is likely to shape the future of woodworking is the increased use of advanced materials. In the past, we were limited to traditional woods such as oak, maple, and cherry. However, in the future, we may have access to new materials that are stronger, lighter, and more durable than traditional woods. These materials could include advanced composites, engineered woods, or even bio-based materials made from sustainable sources.

Whether it’s the adoption of digital fabrication, the focus on sustainability, the advancement of finishing techniques, or the increased use of automation, these developments are sure to shape the way that wood products are designed, manufactured, and consumed in the future.

Thanks for dropping by and please feel free to leave any comments about your thoughts on the future of woodworking, it would be great to hear from you.